3D printing technology, also known as Additive Manufacturing, is a process of creating three-dimensional objects by layering materials. Depending on the printing principles and materials used, 3D printing technologies can be categorized into several types, each with its unique characteristics and applications.

1.Fused Deposition Modeling (FDM)

FDM is one of the most common 3D printing technologies. It works by heating thermoplastic materials (such as PLA or ABS) and extruding them into thin filaments, which are then layered to form an object. FDM is cost-effective, easy to operate, and suitable for prototyping, education, and small-scale production. However, its printing accuracy and surface finish are relatively low.

2.Stereolithography (SLA)

SLA technology uses an ultraviolet laser to cure liquid photopolymer resin, layer by layer, to create highly detailed objects. SLA-printed parts have smooth surfaces and rich details, making them ideal for applications requiring high precision, such as dentistry, jewelry, and precision parts manufacturing. However, the material costs are higher, and post-processing is more complex.

3. Selective Laser Sintering (SLS)

SLS technology uses a laser to sinter powdered materials (such as nylon or metal) to create objects. SLS does not require support structures, making it suitable for manufacturing parts with complex geometries. It is widely used in aerospace, automotive, and medical industries. SLS-printed parts have high strength, but the equipment and material costs are relatively high.

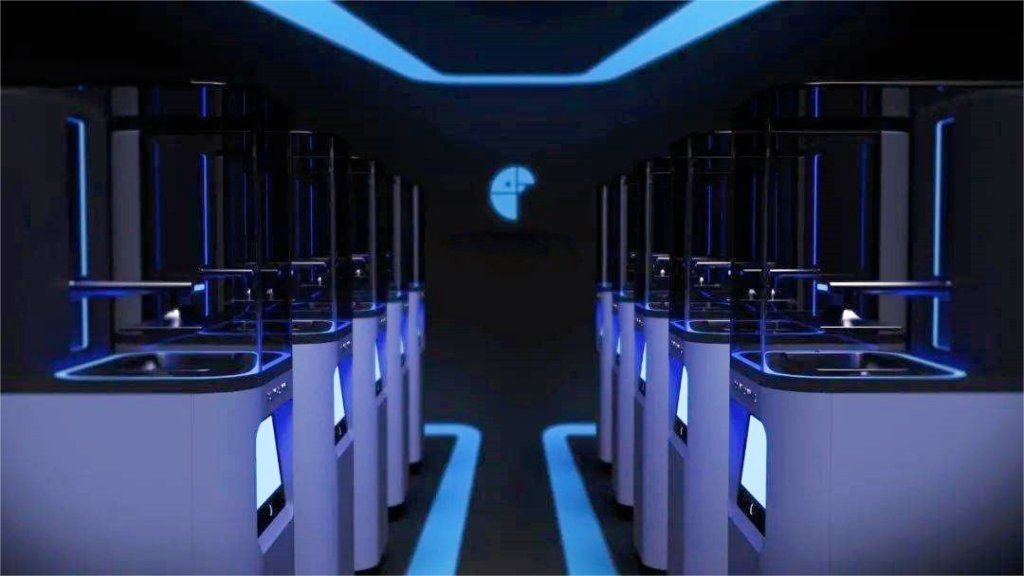

4. Digital Light Processing (DLP)

DLP technology is similar to SLA but uses a projector light source instead of a laser to cure resin. DLP offers fast printing speeds and high precision, making it suitable for dentistry, jewelry, and rapid prototyping. It provides excellent surface quality, but the material options are relatively limited.

5. Metal 3D Printing (DMLS/SLM)

Metal 3D printing technologies, including Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM), use lasers to melt metal powder and build parts layer by layer. These technologies are suitable for manufacturing high-strength, complex metal parts and are widely used in aerospace, medical, and automotive industries. The equipment and material costs are high, but they significantly reduce material waste.

The diversity and flexibility of 3D printing technologies have led to their widespread adoption across various industries. From low-cost prototyping to high-precision manufacturing of complex parts, 3D printing is transforming traditional manufacturing methods and driving industrial innovation.