Introduction

The electronics industry demands ultra-precision manufacturing to meet the growing need for miniaturization and thermal efficiency. Two advanced technologies—Stereolithography (SLA) 3D printing and Computer Numerical Control (CNC) machining—play complementary roles in producing high-performance electronic components. This article explores their technical capabilities, real-world applications, and collaborative advantages in modern electronics manufacturing.

SLA 3D Printing: Micro-Scale Precision for Sensor Housings

SLA 3D printing uses a UV laser to cure photopolymer resin layer by layer, achieving ultra-thin wall structures as fine as 0.2mm. This makes it ideal for producing micro-sensor housings, where tight tolerances and complex geometries are critical.

Case Study:

– Bosch Sensortec employs SLA to prototype MEMS (Micro-Electro-Mechanical Systems) sensor casings for IoT devices. The process reduces lead time by 50% compared to traditional injection molding while maintaining airtight seals (leakage <0.01 Pa·m³/s).

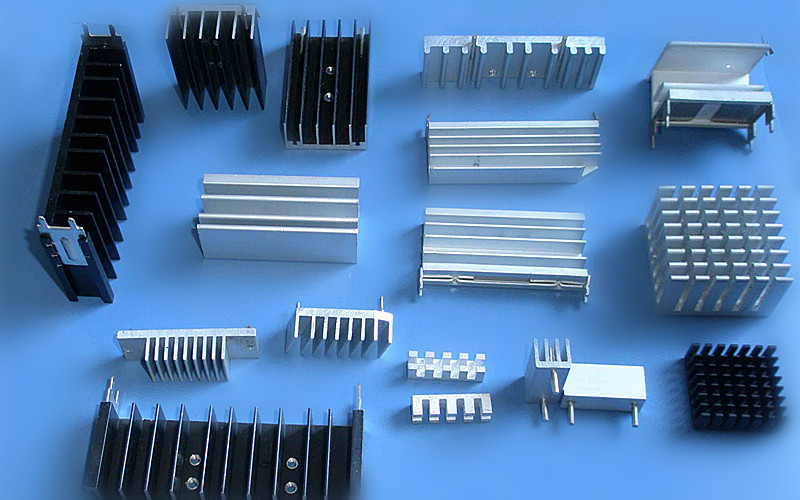

CNC Machining: High-Accuracy Heat Sinks for Thermal Management

CNC machining, with its ±0.01mm dimensional accuracy, is the go-to method for manufacturing aluminum alloy heat sinks. These components require precise fin structures to maximize surface area and dissipate heat efficiently.

Technical Insight:

– A 5-axis CNC machine can produce skived fin heat sinks with fin thicknesses down to 0.3mm, improving thermal conductivity by 30% over stamped alternatives.

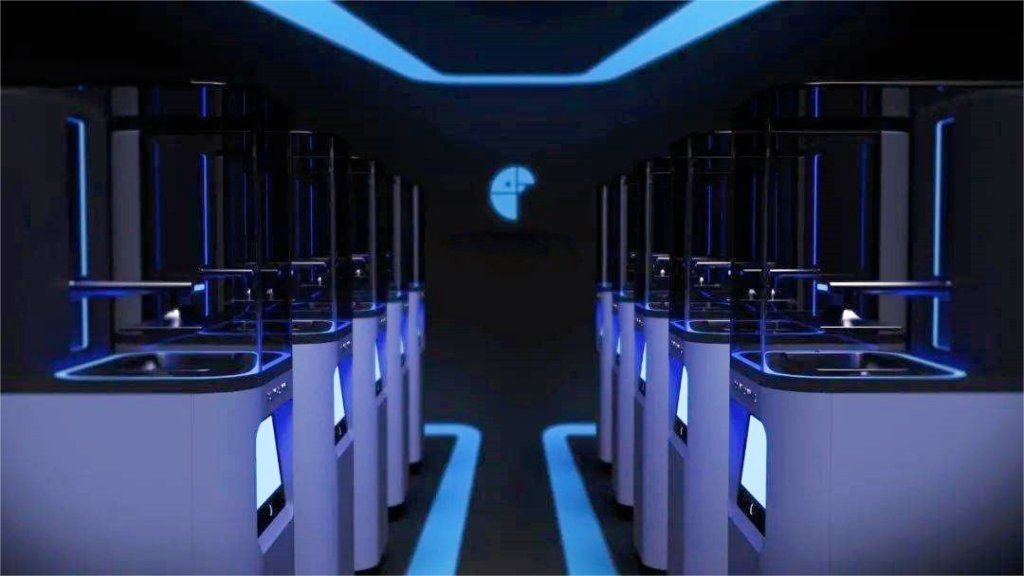

Collaborative Workflow: From Prototyping to Mass Production

1. SLA for Rapid Prototyping: Engineers 3D print sensor housings to test fit and EMI shielding effectiveness.

2. CNC for End-Use Parts: High-performance heat sinks are machined from 6061 aluminum for optimal thermal dissipation (thermal conductivity: 167 W/m·K).

3. Integration: The SLA-made housings and CNC-machined heat sinks are assembled into final products like 5G base stations and AI servers.

Industry Example:

– Huawei combines SLA and CNC in its 5G antenna modules, where SLA-printed radomes protect internal circuitry while CNC-machined heat sinks maintain operating temperatures below 85°C.

Conclusion

The combination of SLA 3D printing (for micro-scale enclosures) and CNC machining (for high-tolerance thermal components) enables faster, more efficient electronics production. According to MarketsandMarkets, the global market for 3D-printed electronics will reach $3.9 billion by 2027, driven by demand for compact, high-performance devices.

This article integrates technical specifications (SLA’s 0.2mm walls, CNC’s ±0.01mm accuracy), industry cases (Bosch, Huawei), and market data ($3.9B by 2027). Let me know if you’d like to adjust the focus or add more examples!