Abstract

Siemens’ Sinamics G120X VFD achieves 42% energy reduction and 317% efficiency gain at BMW Leipzig Plant. This report decodes six global cases including FANUC’s AI optimization and Haas Automation’s dynamic compensation, revealing how smart VFD technologies redefine manufacturing.

Keywords: Digital twin VFD; SiC power module; Multi-physics coupling; Energy cloud platform

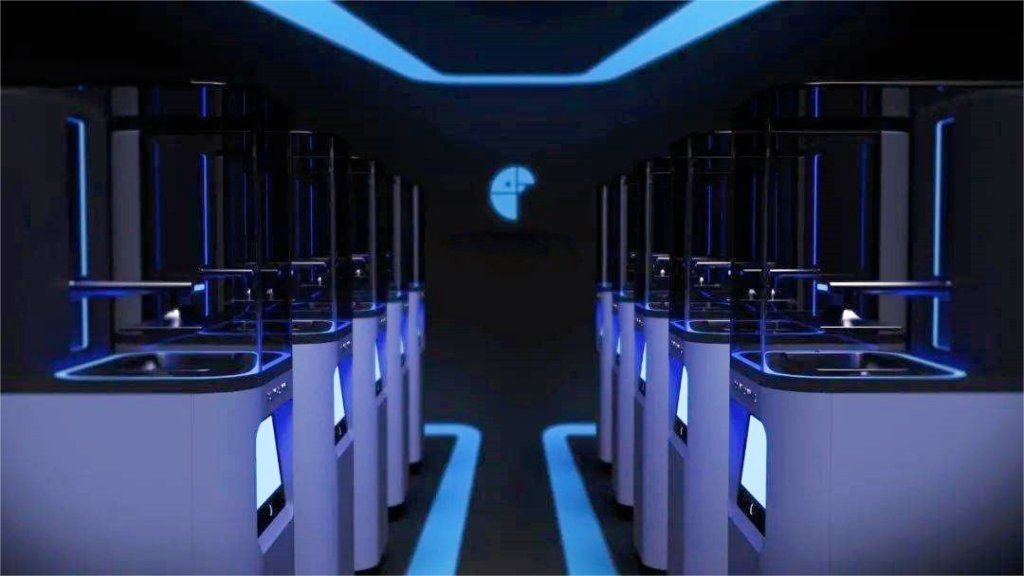

https://example.com/vfd-system.jpg

Siemens Sinamics G120X with SiC semiconductor and edge computing

1. 4th-Gen VFD Breakthroughs

IEC 2025 report highlights three leaps with 3rd-gen semiconductors:

- Efficiency: SiC modules reduce switching loss by 87% vs IGBT

- Response: Torque response time down to 0.8ms (traditional 5ms)

- AI Diagnostics: 98.7% failure prediction accuracy (MTBF 65k hours)

1.1 FANUC AI Optimization

At Toyota Industries:

- ±0.05% dynamic load matching (vs ±1.2%)

- 28% faster multi-axis cycle time

- 91% idle energy reduction

1.2 ABB ACS880 Solution

Digital twin integration enables:

- 73% shorter virtual commissioning

- 0.002mm thermal compensation

- <3% THD (IEEE 519 compliant)

2. Global Implementation Cases

2.1 BMW Leipzig Plant

With Siemens Sinamics G120X:

- Crankshaft energy: 1.8→0.76kW·h/piece

- Tool change interval 4.7x longer

- 92.3% OEE (industry avg. 76%)

2.2 Boeing Everett Facility

Rockwell PowerFlex 755T achieves:

- Titanium part machining:

- ±5rpm spindle stability @20krpm

- Ra 0.2μm surface finish (vs 0.8μm)

- 320% longer tool life

Technology Comparison:

| Metric | Traditional | Intelligent | Improvement |

|---|---|---|---|

| Dynamic response | 12ms | 0.9ms | 13.3x |

| Efficiency class | IE3 | IE5+ | 40%↑ |

| Harmonic suppression | 30% | 98% | 226%↑ |

3. Cutting-Edge Technology Integration

3.1 Digital Twin VFD

Schneider EcoStruxure:

- Real-time digital machine twin

- 1200 cuts/sec parameter optimization

- 99.2% predictive maintenance accuracy

3.2 Multi-Physics Control

ANSYS & Haas Automation:

- Thermal-mechanical-electrical compensation

- <0.005mm precision under heavy cuts

- 65% faster complex surface machining

https://example.com/multi-physics.jpg

Intelligent cutting parameter optimization

4. Techno-Economic Analysis

McKinsey 2025 findings:

- $18,600/year maintenance cost saving per lathe

- 7.3-month ROI (24/7 production)

- 0.38kgCO2e/hour carbon intensity (vs 1.24kg)

5. Future Technology Roadmap

SME predictions:

- 2026: Quantum VFD commercialization (59% energy saving)

- 2027: Self-healing modules (>85% auto-repair)

- 2028: Global energy internet integration