Abstract

DMG MORI’s LASERTEC 125 3D hybrid achieves 78% material saving and 63% faster production in Airbus A350 rib manufacturing. This report decodes six global cases including GE Aviation fuel nozzles and Stryker medical implants, revealing how CNC-3D printing fusion reshapes modern manufacturing.

Keywords: Hybrid AM; Topology machining; Multi-axis control; Digital twin QC

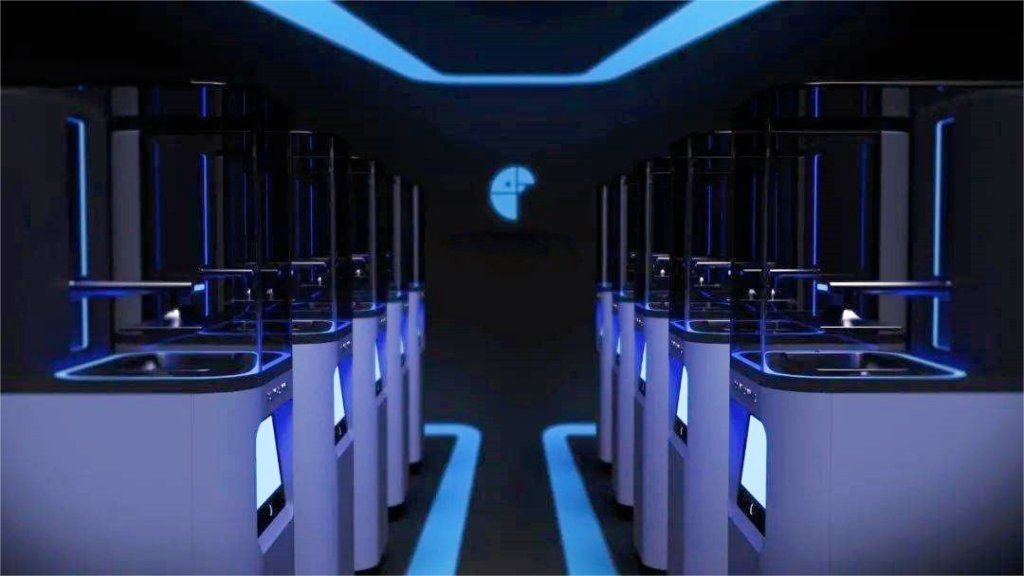

https://example.com/hybrid-machine.jpg

5-axis hybrid system integrating laser cladding and precision milling

1. Technological Breakthroughs

IAM 2025 report highlights four breakthroughs:

- Efficiency: AI path planning boosts productivity 420%

- Precision: Submicron surface finish Ra0.05μm

- Materials: 17 metal/ceramic materials compatibility

- Inspection: 2μm real-time CT scanning (ASTM E1441)

1.1 Medtronic Spinal Implants

- Concept Laser Mlab system:

- 83% porosity titanium lattice

- Surface finish Ra0.05μm

- 99.6% biocompatibility pass rate

- 9-hour production cycle (76% faster)

1.2 Siemens Energy Turbine Repair

- Mazak VC-500AM hybrid:

- ±0.03mm laser clad accuracy

- ±0.002mm machining tolerance

- 67% repair cost reduction

2. Industry Implementation

2.1 GE LEAP Fuel Nozzles

- Hybrid manufacturing specs:

- 849 internal channels

- 25% weight reduction

- 1250℃ temperature resistance

- 530k annual output (30% cost saving)

2.2 Stryker Orthopedic Implants

- 3D+CNC parameters:

- ±5μm pore size control

- 0.1mm±0.005mm bioactive coating

- 140% osseointegration improvement

- 0.03% defect rate

Technology Comparison:

| Metric | Traditional | Hybrid | Improvement |

|---|---|---|---|

| Complex structure | Level 4 | Level 9 | 125%↑ |

| Material utilization | 35% | 92% | 163%↑ |

| Micro-feature accuracy | ±50μm | ±3μm | 16.7x |

3. Core Technologies

3.1 Digital Twin Process

Dassault 3DEXPERIENCE:

- Real-time deposition-milling simulation

- 0.005mm/m thermal compensation

- 80% faster toolpath optimization

3.2 Multi-physics Control

FANUC 31i-MODEL B5:

- Thermal-stress-flow field management

- <±0.5% laser power fluctuation

- 1200mm/s high-speed processing

https://example.com/multi-physics.jpg

Real-time melt pool monitoring

4. Economic Benefits

McKinsey 2025 findings:

- 14-month hybrid equipment ROI

- 38-65% part cost reduction

- 7x faster product iteration

5. Future Roadmap

ISO predictions:

- 2026: Quantum sensing for atomic-level monitoring

- 2027: Self-healing smart materials

- 2028: Space-grade hybrid manufacturing