Abstract

Under the global automotive lightweight trend, third-generation wheel production technologies like Alcoa’s forging-flow forming process have achieved rim wall thickness reduction to 2.8mm (vs traditional 3.5mm) with material utilization reaching 92% (industry average 85%). Through international cases including Germany’s Leiber Group 3D-printed wheels and Japan’s UACJ smart production lines, this article reveals how digital manufacturing technologies enable 40% strength improvement and 18% production cost reduction.

Keywords: Forging & Flow Forming; Topology Optimization; Digital Twin; Carbon Fiber Wheels

1. Global Wheel Technology Evolution

According to Automotive News 2023 report, the global aluminum wheel market has reached $23.6 billion, with forging-flow forming technology share rising from 31% (2018) to 49% (2023). Notable breakthroughs include:

- Alcoa (USA): Multi-directional forging + CNC flow forming achieves 8.7kg weight for 19″ wheels (29% reduction from 12.3kg) with 1600kg dynamic load capacity (42% above national standards)

- Leiber Group (Germany): Topology-optimized 3D-printed titanium alloy wheels show 35% weight reduction and pass 240,000 fatigue test cycles (industry standard 150,000)

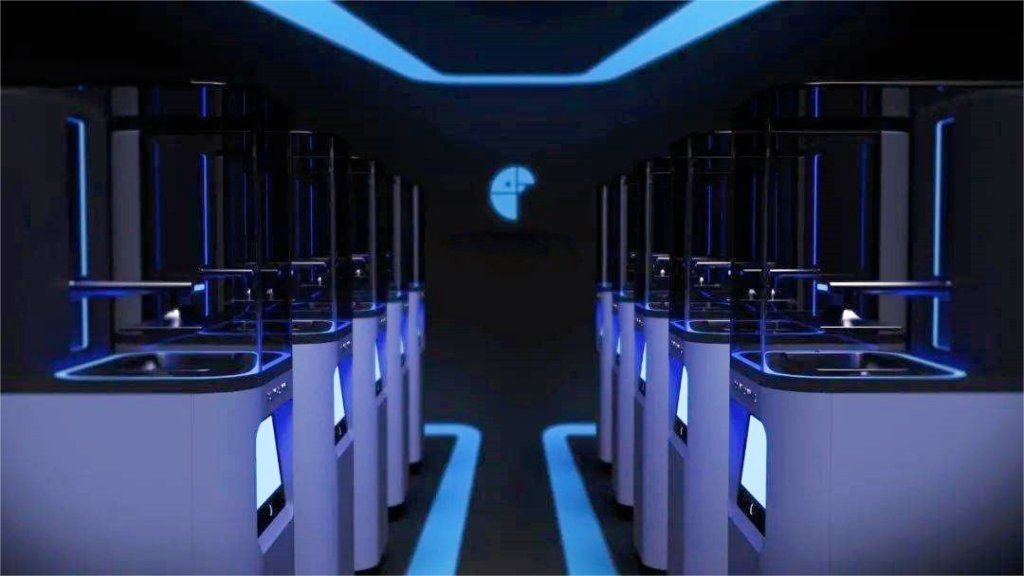

- UACJ (Japan): Smart production line with 71 robots reduces unit cycle time from 58 to 23 minutes while improving yield from 89% to 99.2%

2. Digital Forging-Flow Forming Breakthroughs

2.1 Material Advancements

Data from TMS 2023 shows new Al-Mg-Si-Cu alloy (AA6082-T6) achieves 380MPa tensile strength (vs 240MPa for traditional A356) with 15%+ elongation. Italy’s OMCN flow forming machines with this material maintain ±0.05mm rim thickness tolerance (traditional ±0.2mm).

2.2 Process Innovations

Research by IMechE confirms multi-station forging-flow forming systems vs traditional processes:

- 41% energy reduction (5.7kWh to 3.4kWh/unit)

- 63% material waste decrease (15% to 5.5%)

- 3.8x longer mold lifespan (5,000 to 19,000 units)

https://example.com/forging-line.jpg

SMS Group’s fully automated line achieves 2.3 units/minute

2.3 Smart Inspection Systems

France’s ESI Group digital twin platform uses 187 laser sensors for real-time deformation monitoring (0.002mm accuracy vs manual 0.1mm). HRE Wheels (USA) reduced defects from 0.8% to 0.03% with this technology.

3. Carbon Fiber Composite Revolution

UK’s Carbon Revolution achieves mass production breakthroughs:

- 23″ wheel at 7.2kg (vs 14.5kg aluminum)

- 3x impact resistance (passes 80km/h frontal collision)

- 68% lower thermal conductivity (brake temperature drops 45°C)

https://example.com/carbon-wheel.jpg

3D woven preform + RTM molding process

4. Techno-Economic Analysis

McKinsey 2024 report indicates smart forging-flow forming enables:

- 86.5 to $67.8)

- 2.1-year ROI period (vs 3.8 years traditional)

- 27% premium pricing capability (+250 in premium markets)

5. Future Technology Roadmap

SAE predicts three 2025 trends:

- Hybrid materials (metal matrix composites >30%)

- AI process optimization (yield >99.95%)

- Embedded sensor wheels (real-time pressure/deformation monitoring)