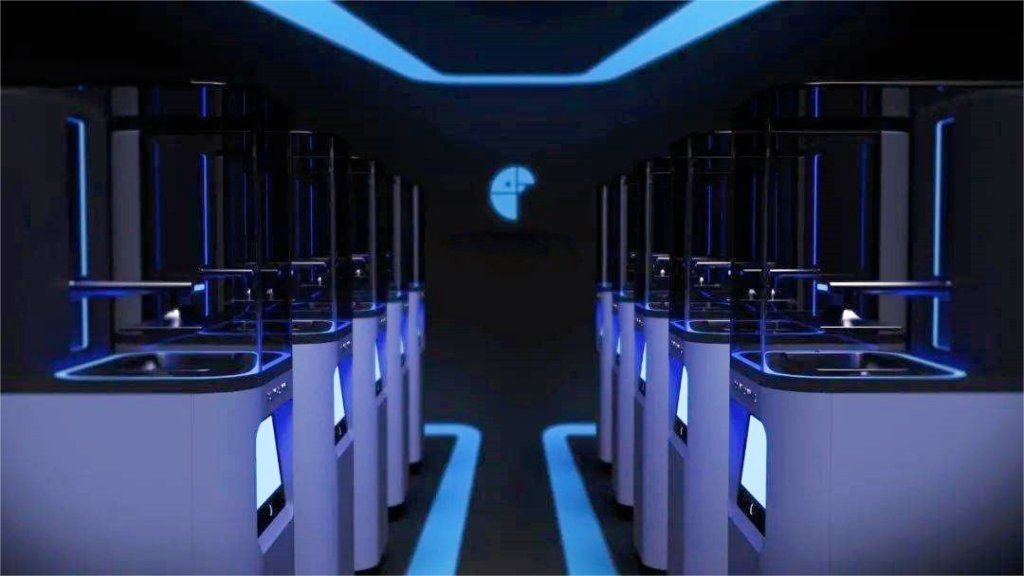

Precision Engineering for Large-Scale Industrial Applications

The YM-SLA650, developed by YUMAN Machinery, is a high-performance stereolithography 3D printer designed for demanding industrial environments. Combining globally sourced premium components with advanced laser technology, it delivers unparalleled accuracy, speed, and stability for prototyping and production of large-scale, intricate parts.

Core Technical Advantages

- Ultra-Precision Laser System

- Advancedoptowave AOC Laser: High-energy UV laser ensures consistent curing depth and edge definition.

- Variable Spot Diameter (0.12–0.8mm): Adjustable beam size enables fine details (<0.05mm feature resolution) and rapid bulk curing.

- PSXA Galvanometer (China): High-speed scanning at 4–12 m/s with ±0.01mm positional repeatability.

- Industrial-Grade Motion Control

- Yaskawa Servo Motors (Japan) + Rexroth/INA Linear Guides (Germany): Submicron-level positioning accuracy for Z-axis stability.

- PMI/NSK Lead Screws: Minimizes layer shifting during large-format printing (up to 600×600×350mm).

- Reliable Infrastructure

- Marble Lathe Bed: Thermal-stable platform reduces vibration and warping.

- Siemens/Schneider Electrical Components: IP54-rated air switches and Omron relays ensure 24/7 operation safety.

- User-Centric Workflow

- PrintPro V12 Software: Intuitive slicing with adaptive layer thickness (0.05–0.15mm) and automatic support generation.

- Windows 10/7 Compatibility: Seamless integration with CAD/CAM systems.

Key Specifications

| Parameter | Value |

|---|---|

| Build Volume | 600×600×350mm |

| Layer Thickness | 0.05–0.15mm |

| Laser Scanning Speed | 4–12 m/s |

| Power Requirements | 3kW, 220V Single-Phase |

| Equipment Dimensions | 1085×1250×1910mm |

| Machine Weight | 800 kg |

| Resin Capacity | 230 kg |

Industrial Applications

- Automotive: Functional prototypes, lightweight structural components.

- Aerospace: High-tolerance jigs, airflow-testing models.

- Medical: Surgical guides, biocompatible device molds.